ACTIVITIES

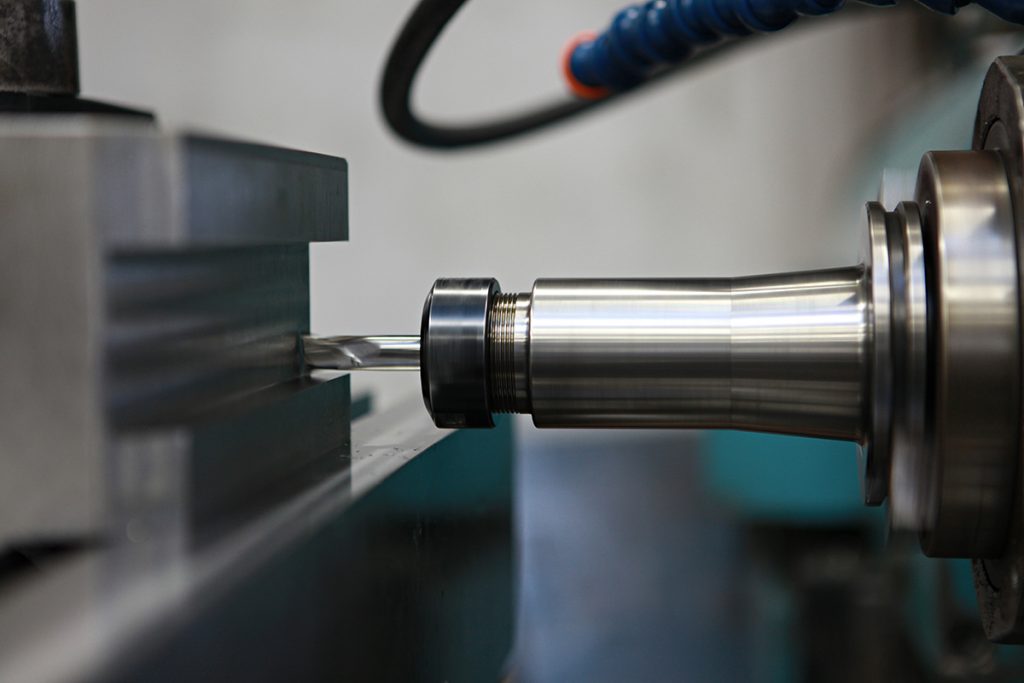

MACHINING / METALWORKING

Manufacturing of new parts on the basis of manufacturing drawings or individual mapping, and improving used parts.

- Turning

- Milling

- Side and surface grinding

Our processing capacity ranges from the very small components to the large work pieces that weigh as much as several tons. Our machinery is a mix of traditional and CNC technology-driven equipment.

CUTTING TECHNOLOGY

Flame cutting machine Type: OMNICOM Messer

working area: 3000 x 6000 x 550 mm

STRUCTURAL CONSTRUCTION, WELDING

Our metalwork plant mainly assembles the structural elements of various machinery and equipment. We also undertake the manufacturing of simpler, fine steel structures.

Welding is performed in our well-equipped welding plant by certified welders who receive continuous training. The renewal certification of our welding plant certification is under way.

IMPLEMENTATION

We undertake to install technological equipment, technological pipelines, plants and plant parts with our separate personnel, not related to the manufacturing activities. Performing daily and periodical machinery maintenance tasks. In cooperation with the electric business line, and complemented with an external construction contractor we also undertake general construction and main contractor tasks.

SPRAYING, PAINTING

We ensure the appropriate roughness of the structure to be painted in our sand-spraying unit. As regards the painting procedures: we have experiences both with aqueous and solvent-based technologies.