ACTIVITIES

MACHINING / CNC

Production of new parts, renovation of used parts and pieces using turning, milling, side and surface grinding processes. Our capacity ranges from the very small components to the large work pieces that weigh as much as several tons.

CUTTING TECHNOLOGY

Our water jet cutter was the first one in Hungary. Cutting parameters: 3000x2000x300 mm. The table size of our 2-head flame cutting equipment: 6000×3000 mm. Cutting width: 350 mm

WELDING

Our metalwork plant mainly assembles the structural elements of various machinery and equipment. We also undertake the manufacturing of simpler, fine steel structures.

IMPLEMENTATION

We undertake to install technological equipment, technological pipelines, plants and plant parts with our separate personnel, not related to the manufacturing activities, and to perform daily and periodical machinery maintenance tasks.

SPRAYING/ PAINTING

We ensure the appropriate roughness of the structure to be painted in our sand-spraying unit. As regards the painting procedures: we have experiences both with aqueous and solvent-based technologies.

MACHENERY DEVELOPMENT

Our activities are aimed at a special segment of mechanical engineering. We primarily manufacture custom machinery and equipment for the steel industry, paper industry and rubber industry, and take part in the renewal and maintenance of such machinery.

REFERENCES

FMT

At the plant HGY2 we performed a fresh air system reconstruction to ensure a capacity increase of 25%. To enable the installation of the new system the existing kiln system was dismantled and modified.

ISD DUNAFERR

Performing the installation works of a grip roller and working roller changing and section adjustment equipment in the hot-rolling millPA total of 6 roller changing framework were installed together with the associated hydraulic systems.

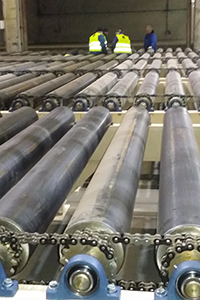

FALCO ZRT.

Instead of the base truck solution the collecting and storage boxes were replaced by a roller table.

ANDRITZ AG.

Production of bath lid lifting structures for the acid bath of continuous sheet galvanizing plant. Over the past two years we have manufactured nearly 40 sets.